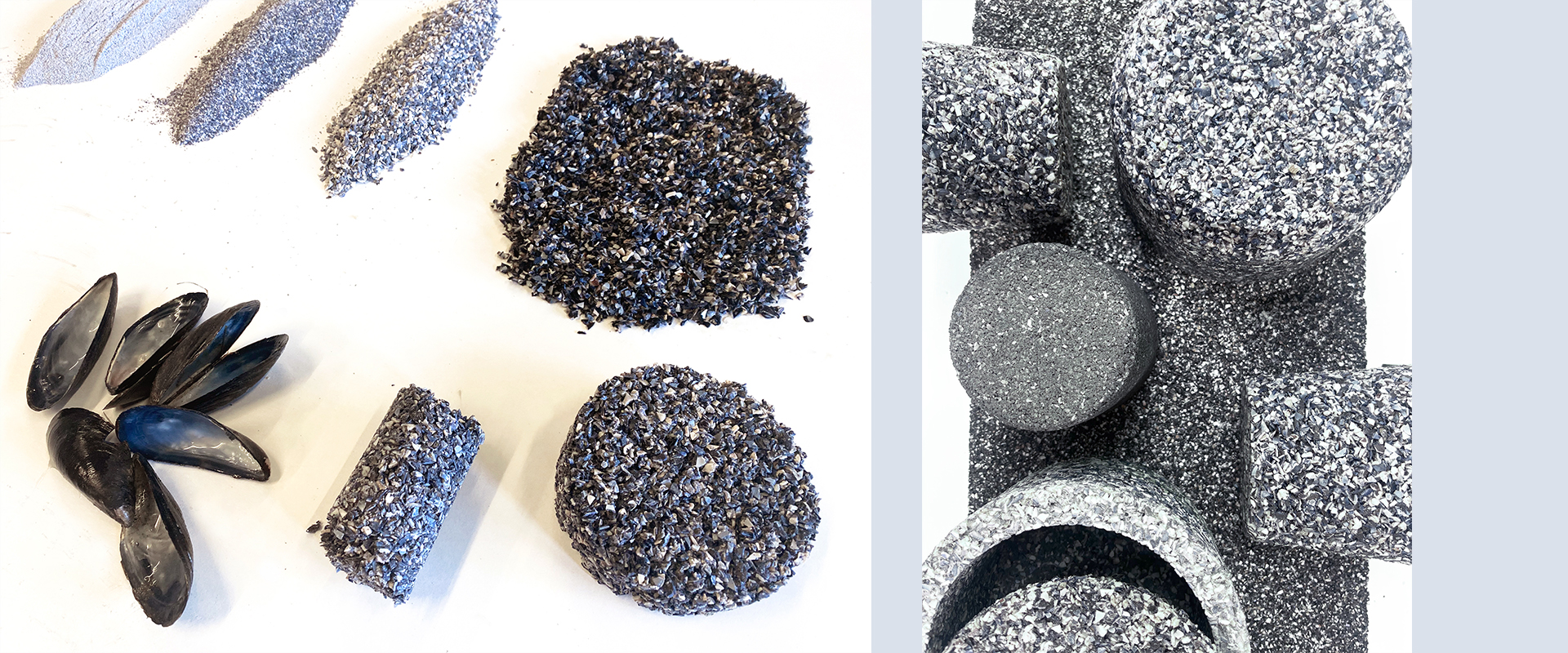

SEASHELL CONCRETE

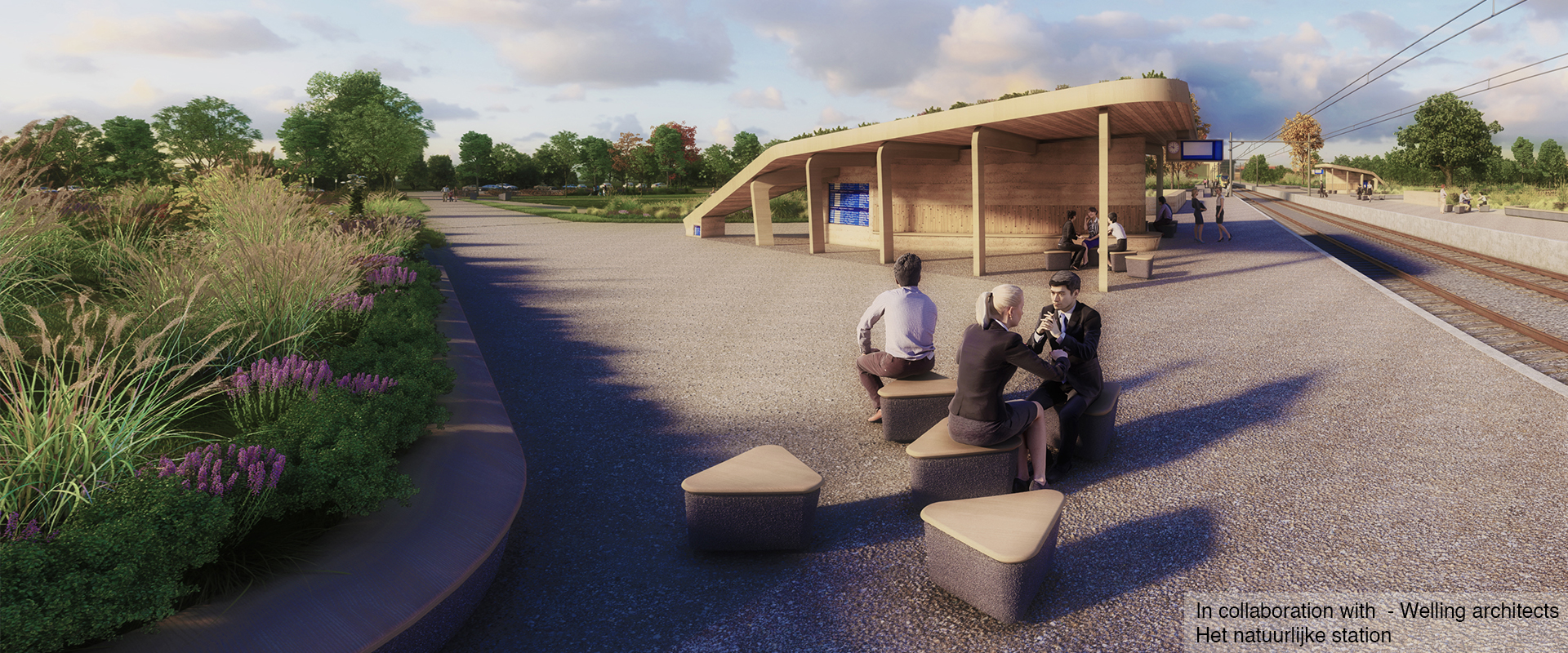

STV was selected to participate in the ‘What If Lab…’, a design-driven intervention program of the Dutch Design Foundation. In this program, designers are deployed to provide answers to complex issues. In this edition, ProRail, together with their partners, asked us to work on a sustainable train station. For this assignment, STV investigated how local buildings can be upgraded into circular building materials. Tjeerd Veenhoven assumed purely organic raw materials that are present in and around the track.

For ProRail, STV developed a sandwich panel made of reed from the Weerribben, a biological composite veneer of natural pigments and bulrush fiber and a concrete substitute for mussel shells from Zeeland. In order to be able to apply these materials, STV has entered into a partnership with Welling Architects, who applied them in The Natural Station. STV sees the cooperation with ProRail as an excellent opportunity to introduce sustainable materials into our daily lives, as we all travel by train at some point. It goes without saying that a building with such an important social function is a forerunner in circular construction, with extra attention for water and biodiversity.